Prepare for CRA compliance as Interniche NicheStack TCP/IP will reach end of general support

We at Tuxera are dedicated to developing products that are secure and resilient against the threats of the connected world....

We are here to help

Have a question or need guidance? Whether you’re searching for resources or want to connect with an expert, we’ve got you covered. Use the search bar on the right to find what you need.

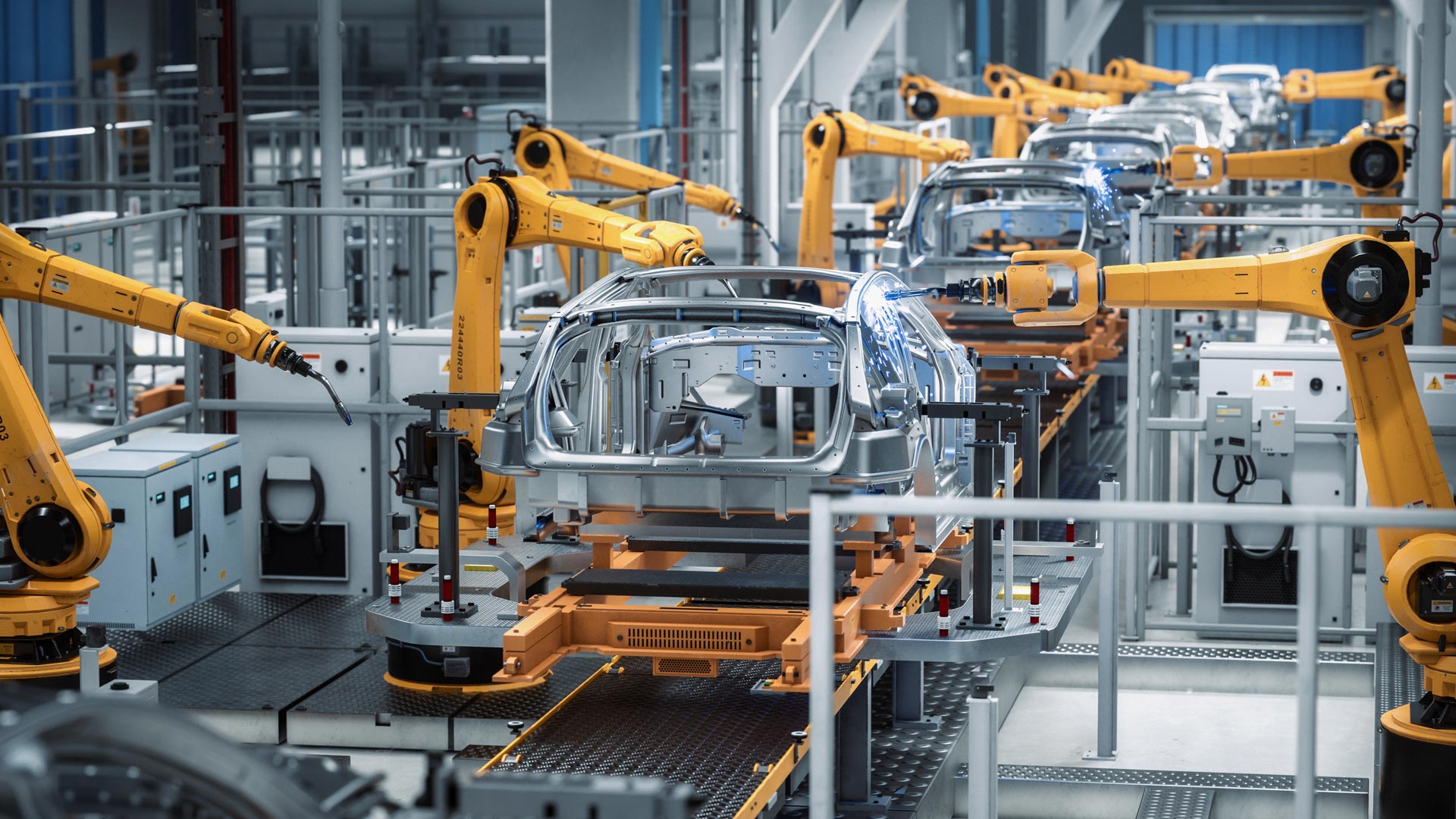

Today’s manufacturing processes are smarter and more data-driven than ever before. Could data be a driving factor for operating system adoption in IIoT?

As we’ve mentioned in the past, the industrial sector has lagged behind in terms of processing power and memory capabilities. The reason: the processors used in manufacturing and industrial environments – programmable logic controllers (PLCs) – only needed to do one or a few tasks. Thus, because there wasn’t any pressing need for complex “brains,” PLCs ran application-layer tasks using real-time operating systems (RTOS) or even no operating system at all (otherwise known as a bare metal environment). But in recent years that’s changed.

Today’s manufacturing processes are smarter and more data-driven than ever before. The industrial market relies on data for its operations and to enable new revenue streams. Data from multiple sensors pours in from various points throughout the process, delivering info about line speed, environmental conditions, equipment conditions, and more – plus the machines also communicate and share data between each other. To crunch, store, and share all of that data requires a robust operating system, along with a way to store the data. Industrial PLCs have very demanding requirements due to the harsh extremes and safety concerns in these environments. The hardware needs to withstand temperature extremes, vibration, and have a long lifetime. Likewise, software that is dependable yet lightweight and flexible is a must-have. Industrial and IoT embedded systems need modular operating systems that can be optimized to fit their unique requirements.

Embedded Linux is a great choice, able to accommodate these needs. Linux has already proven itself across every industry – even in automotive where environmental and safety demands are most taxing. Nonetheless, deploying products based on Linux presents several challenges, like time to market, as well as compliance and legal implications. Embedded software providers like WindRiver, Canonical, and Mentor (a Siemens Business) provide commercial embedded Linux versions that tackle this, without turning their backs on their RTOS offering. The deterministic behavior offered by RTOSes, the need for hard real-time data processing – in industrial control systems, for example – and functional safety requirements all keep the RTOS market and its development alive and relevant. Despite the increasing adoption of open-source embedded Linux and Android platforms (see figure), the proliferation of non-commercial RTOSes points to an optimized co-existence of these platforms – at least for the time being.

Today’s smart industrial sector needs resilient hardware and software to boot. All the data used to make manufacturing operations more efficient needs reliable, fail-safe, and power-safe storage management – and that means more than just the hardware. Data corruption or inefficient reading and writing of data compromises the efficiency of today’s smart industrial operations. When data is critical to a device or business, fail-safe file systems and storage software like EdgeFS™ (formerly Reliance Edge™), NitroFS™ (formerly Reliance NitroTM), Microsoft exFAT by Tuxera™ and Microsoft NTFS by Tuxera™ (formerly GravityCS by Tuxera), and FlashFX Tera™ make all the difference, no matter the operating system behind them.

Our whitepaper “Data trends in the smart manufacturing industry and IIoT markets: implications for the storage stack” looks at trends that are shaping the data storage evolution in the industrial and IIoT markets. You’ll learn what key aspects you need to consider when designing storage solutions to avoid potential roadblocks and build reliable systems for the long term, while maximizing the value obtained from your data. Learn more about data storage trends in IIoT by reading our whitepaper below.

Get the whitepaper here.

The product formerly known as Reliance NitroTM is now NitroFSTM. Discover the latest updates and improvements here https://www.tuxera.com/products/tuxera-nitrofs/

The product formerly known as Reliance EdgeTM is now EdgeFSTM. Discover the latest updates and improvements here https://www.tuxera.com/products/tuxera-edge-fs/

Suggested content for: