The EU Cyber Resilience Act – What is it, and how can Tuxera help you comply?

The EU Cyber Resilience Act (CRA) came into force in December 2024 and its main requirements will apply from December...

We are here to help

Have a question or need guidance? Whether you’re searching for resources or want to connect with an expert, we’ve got you covered. Use the search bar on the right to find what you need.

Imagine your automotive production line stalls because a programmable logic controller (PLC) missed its timing—just a few seconds off, and the conveyor doesn’t sync with the robots. The entire line stops. For some manufacturers, that’s $2.3 million lost every hour. Or picture a chemical plant where a missed pressure reading triggers a costly emergency shutdown.

These aren’t hypotheticals but realities in industrial environments where PLCs collect and act on critical operational data, every second of every day.

In production environments, the focus often falls on large systems like robots and industrial machinery. But it’s the smaller, distributed PLCs running quietly in the background that serve as the data hub of your production system. Each log on its own may seem minor, but together they form the complete picture that guides system planning and key decisions. If your PLCs fail, that picture disappears, and the whole production line could come to a halt.

Let’s dig into why PLC data is so critical and why logging it safely and reliably is more important than ever.

PLCs control industrial automation equipment—like robots, drives, actuators, and entire production processes—while continuously logging operational data. This includes:

In a nutshell, PLCs capture what’s happening in your production line, how it’s working, and when something’s off.

PLCs first receive input signals from sensors and field devices. Based on this data and your programmed logic, they send output signals to actuators, motors, and drives.

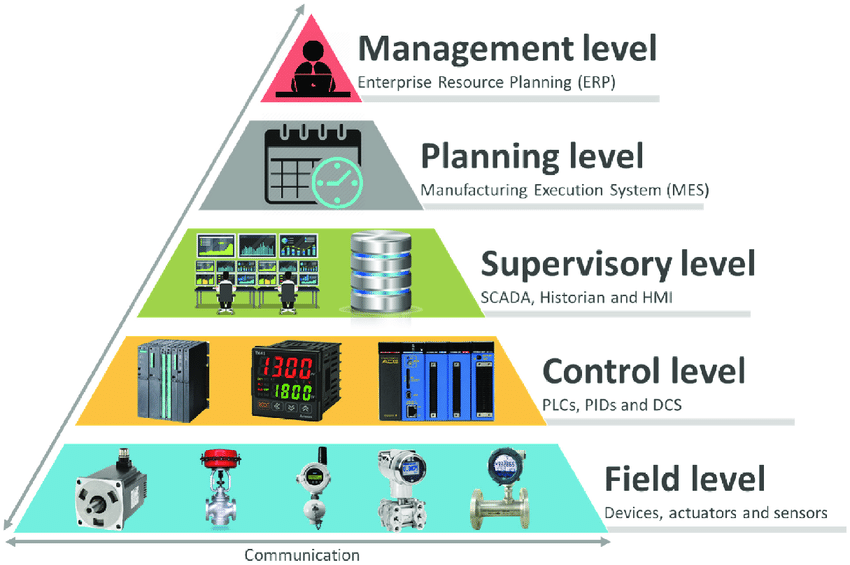

Logging doesn’t stop with PLCs—they’re just the first node in a broader industrial data flow. Data moves from your PLCS through your control system—either a supervisory control and data acquisition (SCADA) system or a human-machine interface (HMI)—into your data historian or manufacturing execution system (MES), and all the way to your cloud or business-level systems.

This data powers everything from the predictive maintenance algorithms that keep your equipment running to the dashboard your operators use.

You can’t fix what you can’t see. And in manufacturing, visibility starts with your PLC logs. Here’s why they’re mission-critical:

If your PLCs fail, the financial impacts are huge. Every second and every byte count, especially in regulated industries like food & beverage, energy, medical devices, and aerospace. Large manufacturers can lose up to 11% of their annual revenue to unplanned downtime—roughly $253 million per facility, per year.

Hourly costs vary by sector, but it’s generally in the six-figure to seven-figure range, with costs climbing due to inflation and higher capacity utilization. Beyond hourly rates, a single downtime event can cost millions once all losses are tallied.

With UK and European manufacturers projected to lose over $100 billion to downtime in 2025, unplanned downtime has become one of the costliest drains on profitability in industrial operations.

PLC logs are often written to flash memory, which is vulnerable to corruption during power loss or brownouts. A sudden shutdown mid-write can compromise not just new data but existing logs as well. Other common risks include flash wear that quietly degrades data over time, and lack of rollback mechanism to recover from errors.

With so much at stake, it’s clear you need reliable PLC data solutions. It’s easy to assume the file system that came with your controller is good enough. But in high-frequency, high-stakes environments, that assumption can be expensive. Ask yourself:

If you’re unsure, your mission-critical logs—and the operations that depend on them—could be at serious risk.

For context, consider this: just one Siemens S7-1500 logging 10 variables at 1 Hz generates approximately 207 MB of data per day. When you scale that across dozens of devices in an AI-driven production line, your file system becomes the backbone of your operational resilience.

When evaluating or upgrading your PLC logging strategy, look for a file system that offers:

Purpose-built solutions like Tuxera EdgeFS are designed to provide deterministic fail-safety and optimize flash memory for embedded systems. While consumer-grade SD cards typically handle around 10,000 write cycles, industrial-grade SLC flash memory can endure more than 100,000. By using a wear-leveling file system, you can extend the lifespan of your memory by up to 10 times.

Your logs are more than just diagnostic tools—they’re your operation’s memory, foresight, and first line of defense. They support every dashboard, audit trail, and preventive fix that helps you avoid costly downtime.

When disruptions can cost millions per hour, even the smallest devices on your production line need robust, reliable embedded software.

Ready to boost your industrial systems with reliable data solutions? Learn more about our industrial automation solutions.

Suggested content for: